Close

Approach Words: Efficiency, Environment Preservation, Sustainability

Public Policy Instruments: Communicative, Financial Mechanism, Organization, Physical Intervention, Planning

The Helwan Cement Company Waste Heat Recovery Project is a new industrial initiative at the Helwan Cement plant in Egypt, marking the first large-scale application of waste heat recovery in the Egyptian cement sector.1

Launched with an investment of USD 30 million, the project is designed to capture heat wasted during cement production and convert it into usable power instead of releasing it into the atmosphere.2

The project envisions “protecting the environment and supporting sustainability” while contributing to Egypt’s national energy security and economic growth.3 It aims to decrease energy consumption, reduce CO₂ emissions, and cut reliance on natural gas, in line with Egypt’s Vision 2030.4

Title: A $30 million waste heat recovery (WHR) system has been commissioned at the Helwan Cement plant to improve energy efficiency and reduce thermal emissions.

Source: Click Here

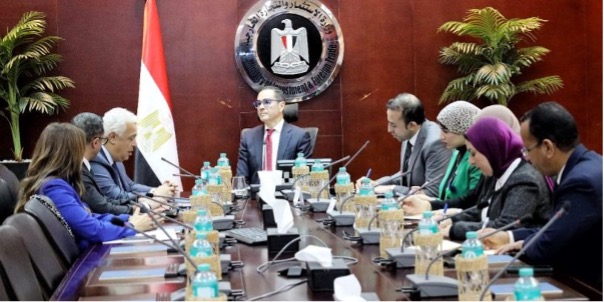

Title: a key ministerial meeting, Heidelberg Materials Group confirmed a $30 million investment to construct a Waste Heat Recovery (WHR) plant at its Helwan Cement Factory

Source: Click Here

Title: The Helwan Cement Company's Waste Heat Recovery (WHR) factory.

Source: Click Here

Title: Operational personnel conducting routine maintenance and system integrity checks on the Waste Heat Recovery (WHR) unit during live operation.

Source: Click Here

To implement its vision, the project integrates advanced waste heat recovery technologies with existing production lines at the Helwan plant.5 Its main components include:

Beyond its technical systems, the project forms part of Heidelberg Materials Egypt’s broader sustainability strategy,10 which focuses on diversifying energy sources and replacing coal and petcoke with alternatives such as biomass, municipal and industrial waste. contributing that would otherwise be disposed in landfills. This approach supports both climate action and circular economy goals, as waste that would otherwise end up in landfills is repurposed into fuel.11

Owner/Developer

Consultant/Designer

Contractor/Implementer

The project was developed and implemented by Heidelberg Materials Egypt, owner of the Helwan Cement plant with a production capacity of approximately 10 million tons of cement annually.12 Initially announced by the Suez Cement Group of Companies (SCGC), before its corporate restructuring under Heidelberg,13 the project’s budget grew from US$20 million to US$30 million, reflecting an expanded commitment to sustainability.14 It was formally inaugurated by H.E. Minister Kamel al-Wazir, Egypt’s Deputy Prime Minister for Industrial Affairs and Minister of Transportation and Industry.15

As first-of-its-kind model Egypt’s cement industry, the Helwan Cement Company Waste Heat Recovery Project demonstrates how industrial operations can integrate environmental responsibility with economic efficiency.16 It sets a regional precedent for sustainable manufacturing practices, reinforcing Egypt’s path toward greener and more resource-efficient industry.17

Project Link

https://www.heidelbergmaterials.eg/en

Endnotes

N.A.

References